What we make

The world’s most advanced and efficient power delivery technology

Manufacturing

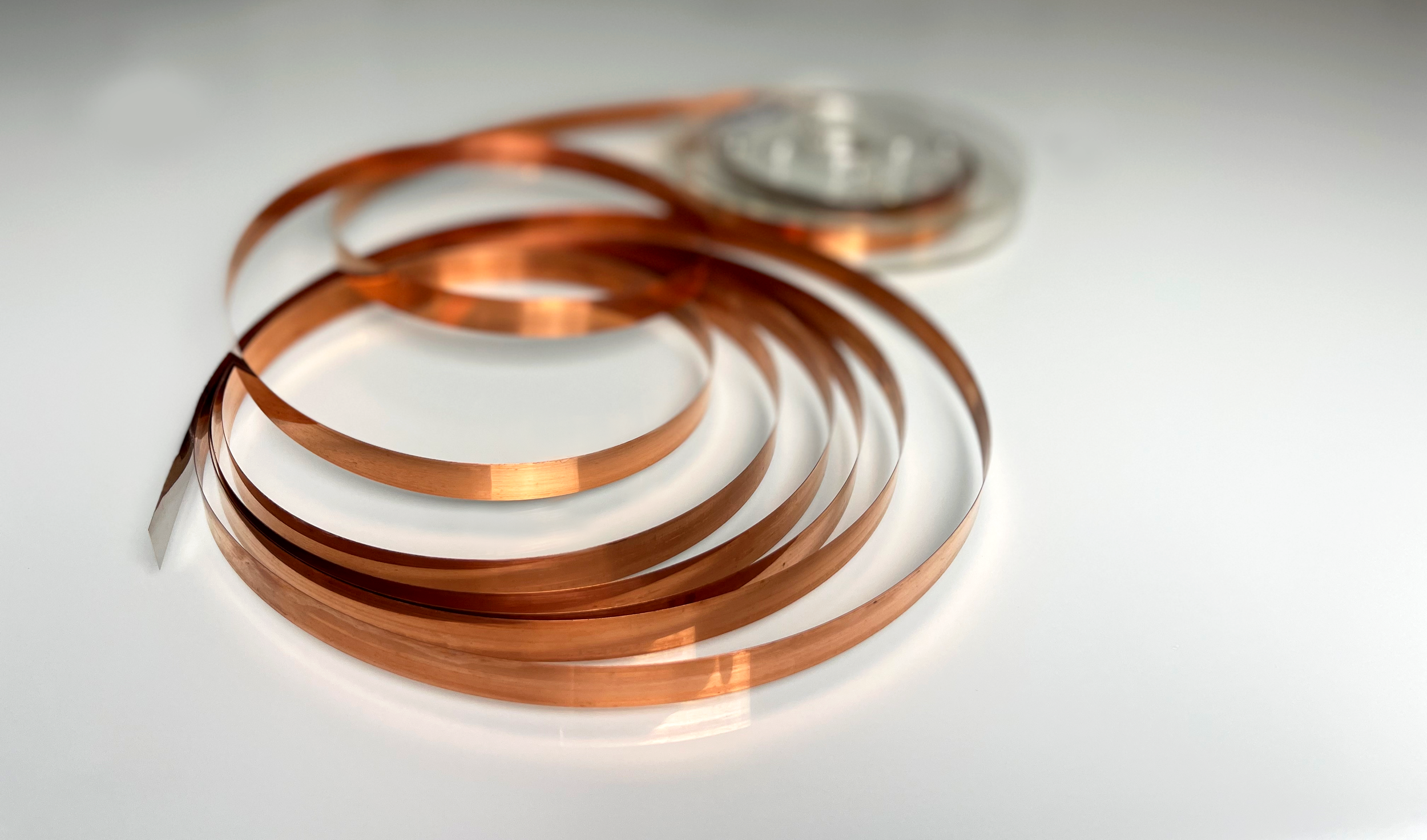

Xeus™ Wire, our advanced conductor technology, is manufactured using an enhanced and proprietary production process.

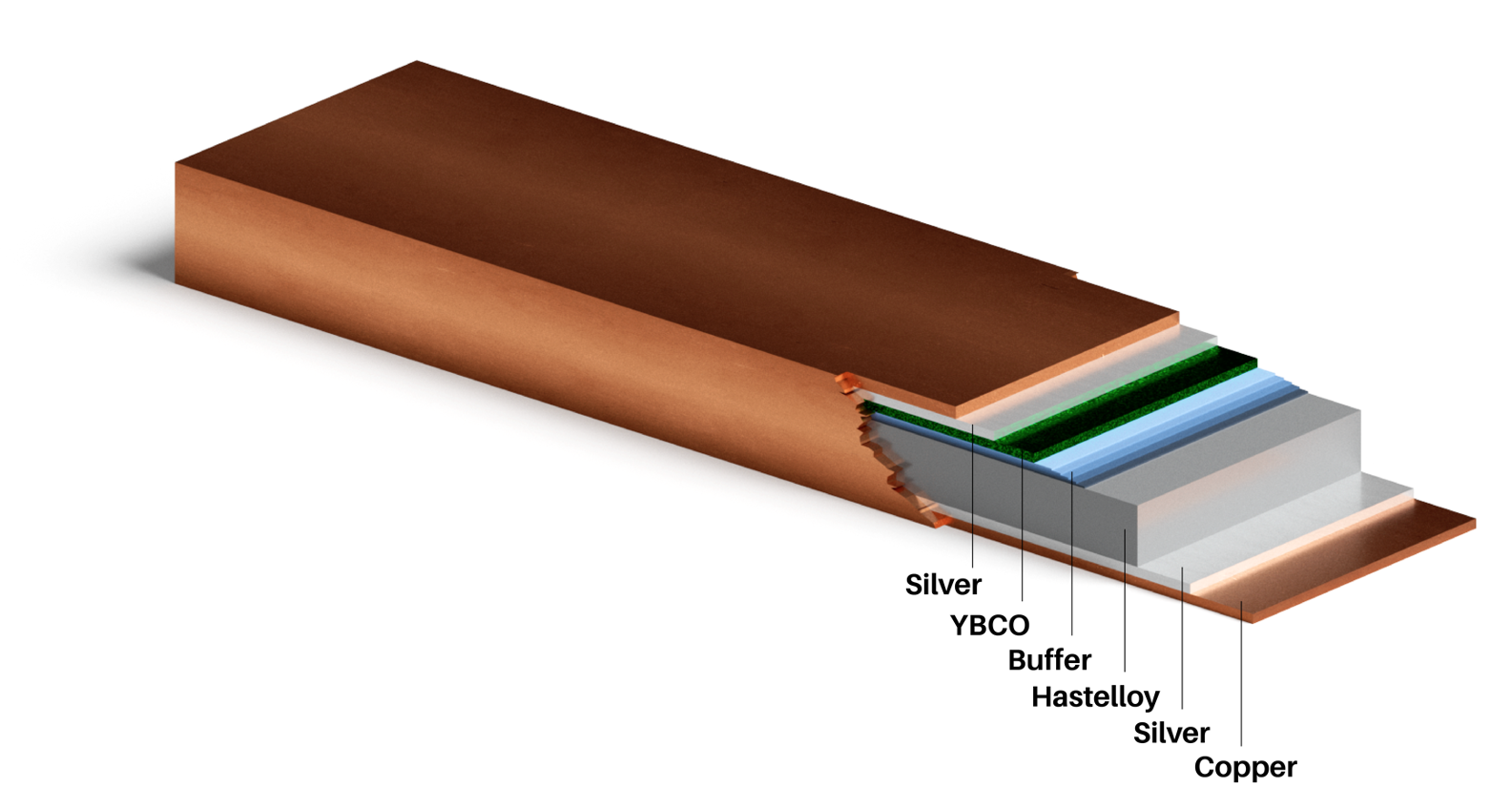

Xeus™ is fabricated using advanced MOCVD manufacturing in a continuous reel-to-reel production. The superconducting layer is deposited on a thin substrate that is then covered with protective coatings. HTS wire has a smooth tape-like structure and is neatly packaged on custom reels for ease of use.

Superconductor Technology

High Temperature Superconducting wire (HTS)

HTS is an advanced conductor technology that when cooled with liquid nitrogen, can deliver ~250x the current-carrying capacity of traditional copper wire, and when used in cables, can increase capacity by 5-10x with essentially no line loss.

HTS can perform as a superconductor in very high magnetic fields, enabling use in power generation and advanced devices. Its many unique properties include:

Very high current flow

Zero electrical resistance

High magnetic field performance

Xeus™ HTS Wire

Xeus™ wire is MetOx’s proprietary brand of HTS wire. Xeus™ is designed to operate at much higher temperatures and can produce much higher stronger magnetic fields than low temperature superconducting wire (LTS). MetOx proprietary manufacturing process is the most advanced in the world for large scale HTS wire production.

Large scale production of HTS allows for widespread adoption in a variety of applications.

Process Engineering & Metrology

Process engineering and advanced metrology ensures the crystal lattice structure is consistently maintained down the length of the HTS wire

Advanced Process Engineering

MetOx is continually expanding our IP portfolio which already includes materials, processes and equipment. Our advanced production system, with industry leading process engineering for quality is the solution for building a cost-effective and scalable supply of HTS over the long term.

Scalability

MetOx built its process specifically for scalable production of affordable HTS wire, for both magnets and cables. Our integrated manufacturing process combines the proven industrial capability of MOCVD with our proprietary technology for HTS wire.

Our leadership team has experience designing and building equipment for large scale CVD and advanced materials production.